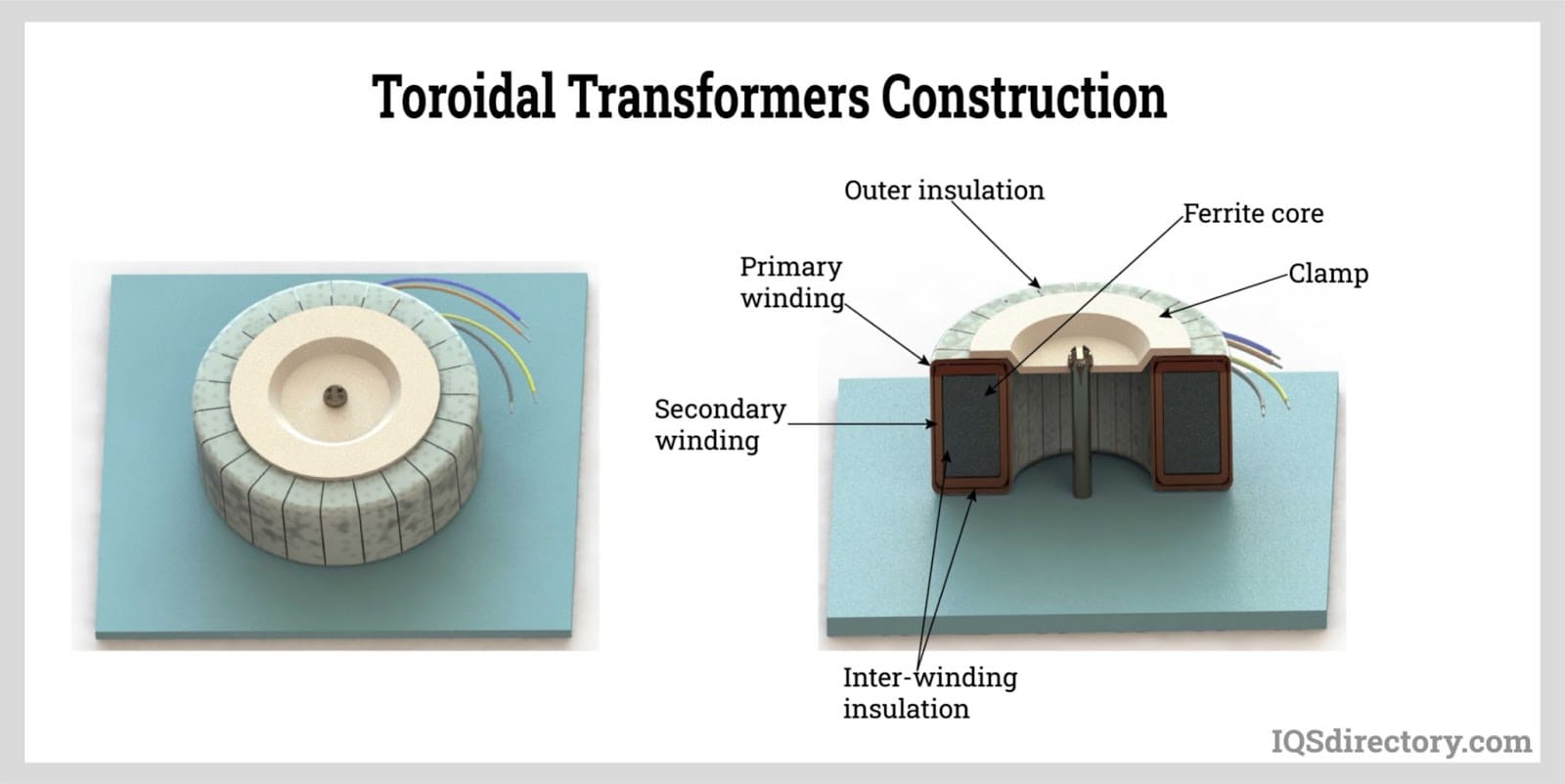

A toroidal transformer is an electrical transformer with a torus or donut-shaped core. The torus core’s surface is covered by its primary and secondary windings, spaced apart by an insulating substance. Any magnetic flux leakage is minimized in this design. Toroidal transformers provide several advantages over conventional square and rectangular-shaped transformers, making them appropriate for delicate and important electronic circuits. Read More…

With more than 500 current transformer manufacturers in the world, Triad Magnetics realizes you have a choice. Why choose Triad? Having served the needs of many industries for more than half a century, Triad believes its experience makes the difference. And if there is one point experience has taught it, it is that it must remain flexible and adaptable to the changing needs of the market.

At CES Transformers, we dedicate ourselves to designing and manufacturing high-quality electric transformers that power industrial, commercial, and utility applications across the nation. We take pride in combining advanced engineering with decades of hands-on expertise to deliver reliable performance and lasting value. Every transformer we build reflects our commitment to precision, safety, and...

At Spang Engineered Solutions, we specialize in designing and manufacturing high-performance electric transformers that meet the demands of today’s advanced power and control systems. We take pride in engineering solutions that go beyond standard components, combining innovation and precision to deliver superior magnetic and electronic performance.

Established in 1973 manufacturing a wide variety of custom transformers and inductors. Transformer products range from small PC transformers to single-phase units with capacities between 10mW and 25KVA, as well as three-phase transformers from 7VA to 75KVA.

At Olsun Electrics Corporation, we specialize in crafting high-quality electric transformers designed to meet the diverse needs of our customers. Our expertise extends to providing comprehensive solutions that encompass design, manufacturing, and testing, ensuring that every transformer we produce delivers exceptional performance and reliability.

More Toroidal Transformer Manufacturers

Compared to conventional shell and core-type transformers, toroidal transformers offer greater design freedom, efficiency, and compactness. They are the perfect solution for low-KVA of up to 15 KVA-rated devices and machinery used in industrial, medical, audio applications, and renewable energy.

Toroidal Transformer Operating Principle

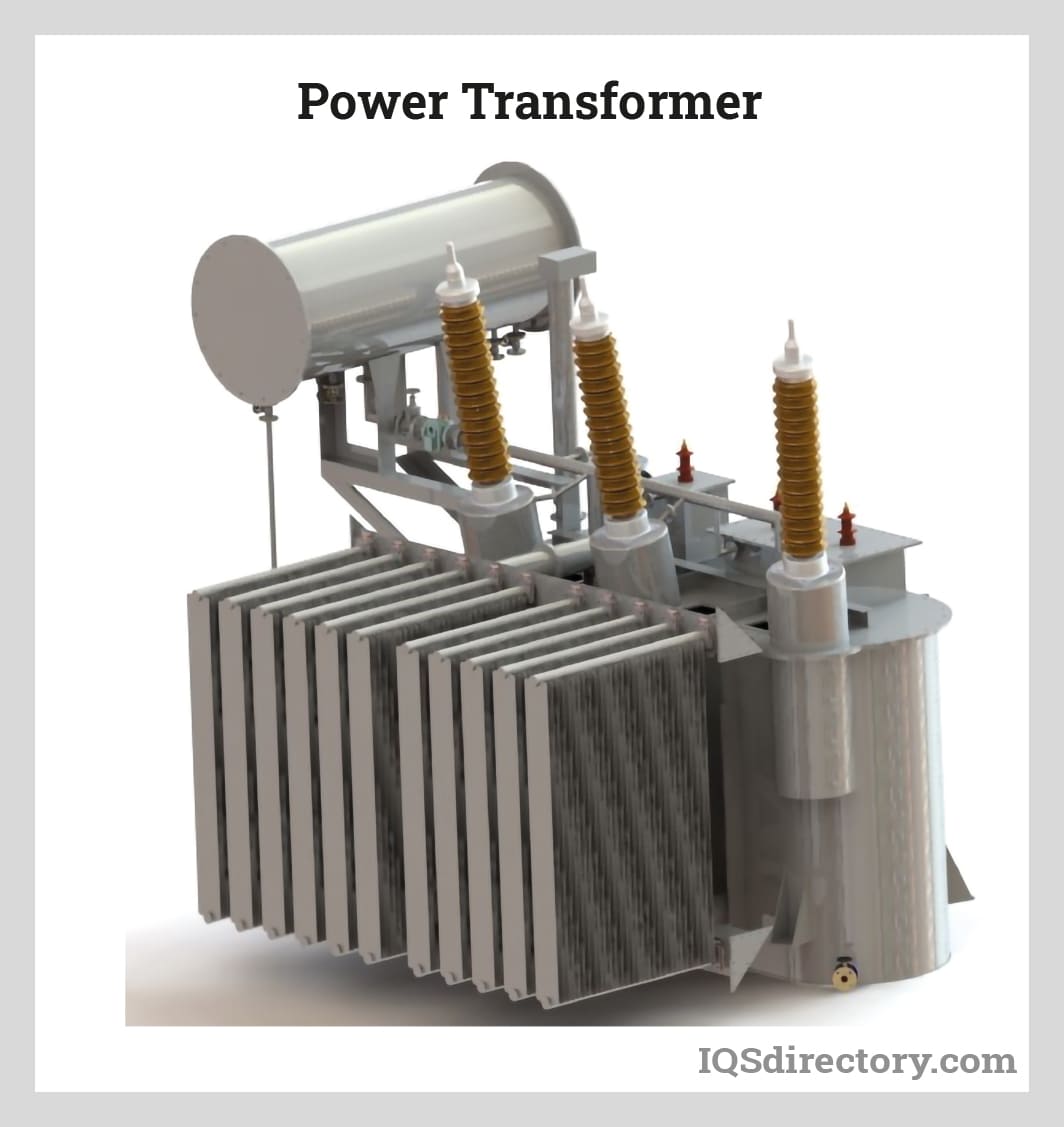

A passive electrical transformer uses a magnetic field to create an electromotive force to move electricity from one circuit to another. The circuits are electrically segregated from one another while this is being done. Transformers are used to change the voltage without altering the frequency of the current flow as it steps up or down the voltage. Faraday's law of induction is the basis for how electrical transformers function.

This physical equation describes the connection between the induced electromotive force and the rate at which a magnetic flux changes. A magnetic flux is produced when magnetic field lines go through a conductor. It was discovered that placing a conductor close to a magnetic field with variable amplitude causes that conductor to produce an electric current.

Solenoids and toroids are the two types of transformer core forms. In order to be considered a solenoid, the conductor must be long and thin and coil up into numerous, close-knit loops. A perfect toroid would completely contain the magnetic flux, similar to a perfect solenoid. In contrast to the absence of magnetic flux density outside the coil, it is concentrated inside.

A toroid core's optimal design is significantly more attainable than a solenoid's. Since it is set up as a loop, it does not have to be indefinitely long. The only prerequisite for a flawless design is to wind the toroid as a whole with windings that are uniformly and tightly coiled. This is probably why Faraday employed a toroidal core rather than a solenoid when he discovered induction. A toroid's circular design makes it simple for the magnetic flux to form a loop without needing an additional return path.

Advantages of Toroidal Transformers

High Efficiency

With typically between 95 and 99% efficiency, toroidal transformers are more efficient than other transformers. This is due to the design's near-optimal construction, which perfectly seals the magnetic flux within the windings. As a result, there is no flux leakage. The magnetic flux is effectively used to couple the main and secondary windings because it is concentrated inside the coil windings, and the windings are uniformly distributed throughout the toroid core.

Electromagnetic Shielding

Toroidal cores naturally insulate nearby components against electromagnetic interference due to the efficient magnetic flux (EMI) containment. They are ideal for electronic devices with delicate components because of this property.

Lower Off-load Losses

Off-load losses occur when the transformer's core is magnetized even though no load is attached to the secondary circuit. As a result, transformers frequently use energy even when they are on standby. Due to their efficient construction, core losses in toroidal transformers are smaller than in regular solenoid-core transformers. Toroidal has fewer off-load losses as a result.

No Air Gap

In contrast to solenoid cores, which have a continuous structure with a significant air gap, toroidal cores are built differently. Air gaps contribute to various detrimental impacts, including noise and the propagation of magnetic flux, or fringing. Three air gaps are present in a typical solenoid core, such as an EI core. Magnetic flux leaks travel via nearby exterior parts at these sites.

Lower Heat Generation

Transformer electrical energy losses eventually result in vibrations and heat. Hysteresis, copper resistance, and eddy currents are the main sources of heat generation. Due to their great efficiency, toroidal transformers produce less heat and can operate without coolant or heat sinks.

Disadvantages of Toroidal Transformers

Expensive Construction

Toroidal transformers are more expensive to produce than other types of transformers, having lower profiles and requiring fewer materials.

Higher Inrush Currents

When the transformer is switched on, there is a surge in the current known as inrush current. This is caused by the primary circuit using a lot of initial currents when the secondary circuit is coupled to a load. In highly efficient transformers like toroid transformers, the amount of inrush current is larger.

Suitable For Single Phase Application

The use of toroidal transformers is restricted to single-phase systems. Three-phase toroidal transformers are marketed but are less common than the more traditional core and shell-type transformers. Only specific applications require the usage of three-phase toroidal transformers.

Application of Toroidal Transformers

- Power supply systems

- Power inverters

- Audio systems

- Control equipment

- Other electronic devices

Choosing the Correct Toroidal Transformer Supplier

For the most productive outcome when purchasing toroidal transformers from a toroidal transformer supplier, it is important to compare several suppliers using our directory of toroidal transformer companies. Each toroidal transformer supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each toroidal transformer business website using our patented website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple toroidal transformer businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services