Auto transformers, a type of electrical transformer, play a crucial role in numerous power systems and applications. Unlike conventional transformers, auto transformers have a unique design that offers distinct advantages in terms of size, weight, and cost-effectiveness. Read More…

With more than 500 current transformer manufacturers in the world, Triad Magnetics realizes you have a choice. Why choose Triad? Having served the needs of many industries for more than half a century, Triad believes its experience makes the difference. And if there is one point experience has taught it, it is that it must remain flexible and adaptable to the changing needs of the market.

At Acutran, we present ourselves as a dedicated manufacturer of electric transformers engineered to deliver dependable power conversion, long-term reliability, and consistent performance in demanding electrical applications. We design and build transformers that support efficient voltage regulation, electrical isolation, and system protection across industrial, commercial, and OEM environments.

At Prem Magnetics, Inc., we present ourselves as a dedicated manufacturer of electric transformers engineered to deliver reliable power conversion, electrical isolation, and consistent performance across demanding industrial and OEM applications. We focus on designing and producing transformers that support efficient energy transfer, stable voltage regulation, and long service life.

Established in 1973 manufacturing a wide variety of custom transformers and inductors. Transformer products range from small PC transformers to single-phase units with capacities between 10mW and 25KVA, as well as three-phase transformers from 7VA to 75KVA.

At Foster Transformer Company, we present ourselves as a dedicated manufacturer of electric transformers designed to deliver reliable power conversion, electrical isolation, and consistent performance across a wide range of industrial and OEM applications. We focus on building transformers that operate efficiently, manage heat effectively, and maintain stable electrical characteristics over long...

More Auto Transformer Manufacturers

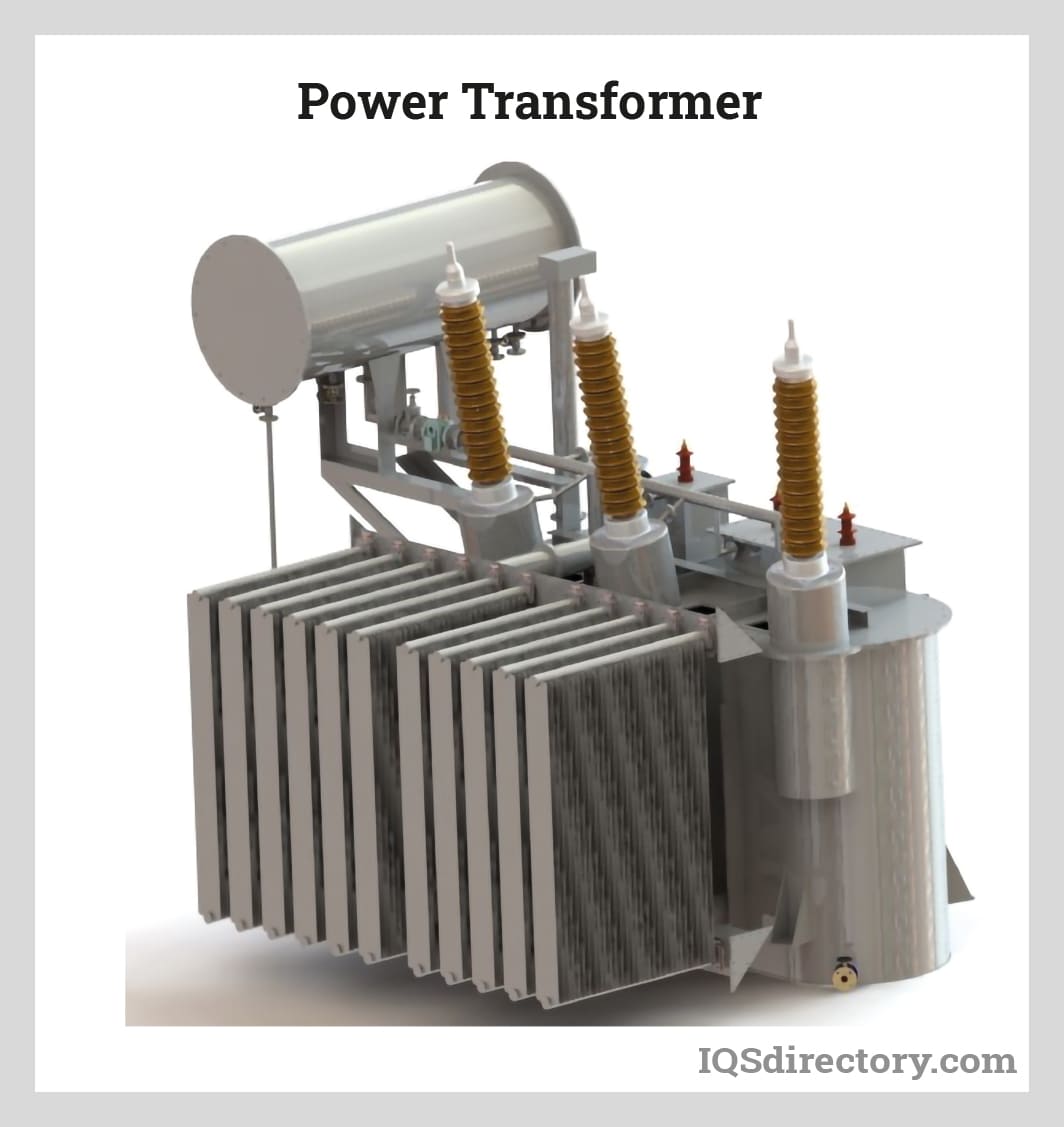

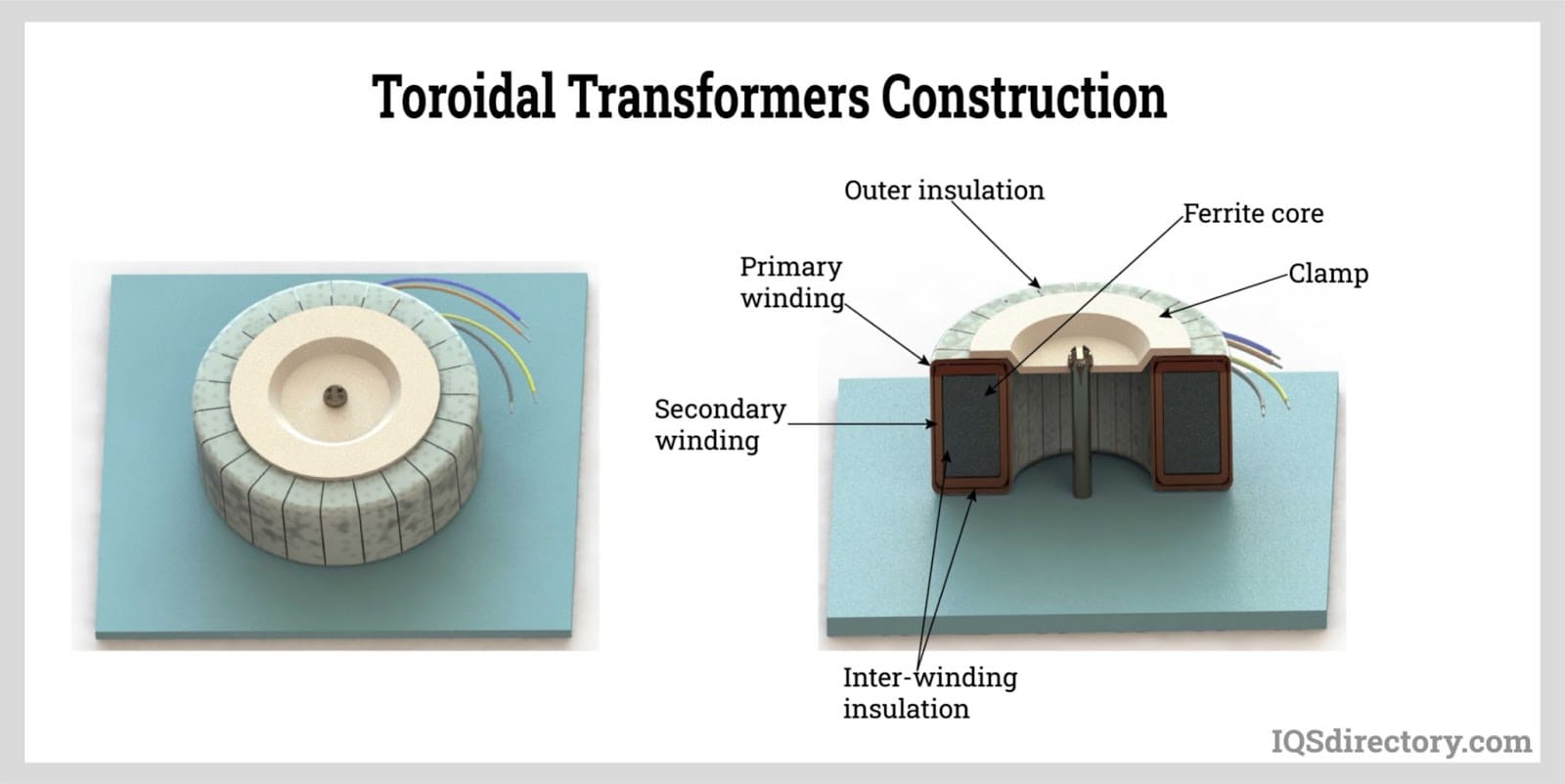

Components Common to All Transformers

Every transformer, including auto transformers, consists of essential components such as a core, windings, a magnetic field, and voltage regulation mechanisms. These components work together to transfer electrical energy between circuits.

Unique Design and Components of Auto Transformers

Auto transformers differ from other transformers due to their specific design elements. Unlike conventional transformers with separate primary and secondary windings, auto transformers feature a shared winding that acts as both the primary and secondary winding. This configuration allows for tap points along the winding, enabling various voltage ratios and voltage adjustment capabilities. The result is a more compact and lightweight transformer with reduced cost compared to traditional designs.

Variations of Auto Transformers

Auto transformers come in various forms to cater to specific applications. One variation is the three-phase auto transformer, employed in industrial power distribution systems to efficiently transfer electricity across three-phase networks. Step-up/step-down auto transformers are also widely used for voltage conversion in electrical appliances, ensuring compatibility with different power sources.

Considerations of Auto Transformers

While auto transformers offer significant advantages, they do present some considerations. One consideration is their limited isolation between the primary and secondary windings, which can compromise safety and protection. Additionally, the common winding in auto transformers may experience higher current compared to traditional transformers, requiring appropriate precautions. Another risk is the potential for cascading faults, where a fault in one section of the winding can affect the entire winding.

Addressing These Considerations

To address these considerations, proper insulation and grounding are essential in auto transformer installations. Adequate insulation between primary and secondary windings minimizes the risk of electrical faults and ensures safety. Protective measures like fuses and circuit breakers help prevent excessive current flow and mitigate potential hazards. Regular maintenance and inspections are also crucial to detect any faults or issues promptly, ensuring the safe and reliable operation of auto transformers.

Benefits of Auto Transformers

Auto transformers offer a multitude of benefits that make them highly advantageous in various power applications. One of their key advantages is their compact size and reduced weight. Compared to traditional transformers with separate windings, auto transformers eliminate the need for duplicate coils, resulting in a more space-efficient design. This compactness is particularly valuable in applications where space is limited, such as in urban areas or within electrical panels. Additionally, auto transformers are cost-effective solutions. By utilizing a shared winding, they require fewer materials and components, resulting in lower manufacturing and installation costs. This cost-effectiveness makes auto transformers an attractive choice, especially in large-scale projects where multiple transformers are needed.

Another significant benefit of auto transformers is their higher efficiency and lower losses. With fewer windings and a reduced magnetic path, they achieve higher energy transfer efficiency compared to traditional transformers. This improved efficiency translates into reduced power consumption and cost savings over the transformer's lifespan. Additionally, auto transformers contribute to voltage stabilization and regulation. They are capable of adjusting the output voltage by tapping different points along the winding, allowing for precise voltage control and ensuring a stable power supply. This feature is crucial in applications where voltage fluctuations can cause damage or affect the performance of sensitive equipment.

Furthermore, auto transformers offer improved voltage quality. By regulating and stabilizing the output voltage, they help mitigate voltage sags, surges, and harmonics. This enhanced voltage quality leads to better performance and reliability of connected devices, reducing the risk of equipment damage and downtime.

Applications of Auto Transformers

The versatility of auto transformers is reflected in their wide-ranging applications. They are extensively used for voltage regulation in power grids, ensuring a consistent and optimal supply of electricity. In industrial settings, meanwhile, auto transformers play a vital role in controlling motor speed in machinery, enhancing efficiency and performance. They additionally find application in audio equipment and amplifiers for precise voltage control, delivering high-quality sound output. Auto transformers are also integral components of electrical distribution systems, renewable energy installations, welding equipment, battery charging stations, and railway traction systems, enabling efficient power transfer in these, and other, diverse scenarios.

Choosing the Correct Auto Transformer Manufacturer

To ensure you have the most constructive outcome when purchasing auto transformers from an auto transformer manufacturer, it is important to compare several companies using our directory of auto transformer manufacturers. Each auto transformer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each auto transformer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple auto transformer companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services