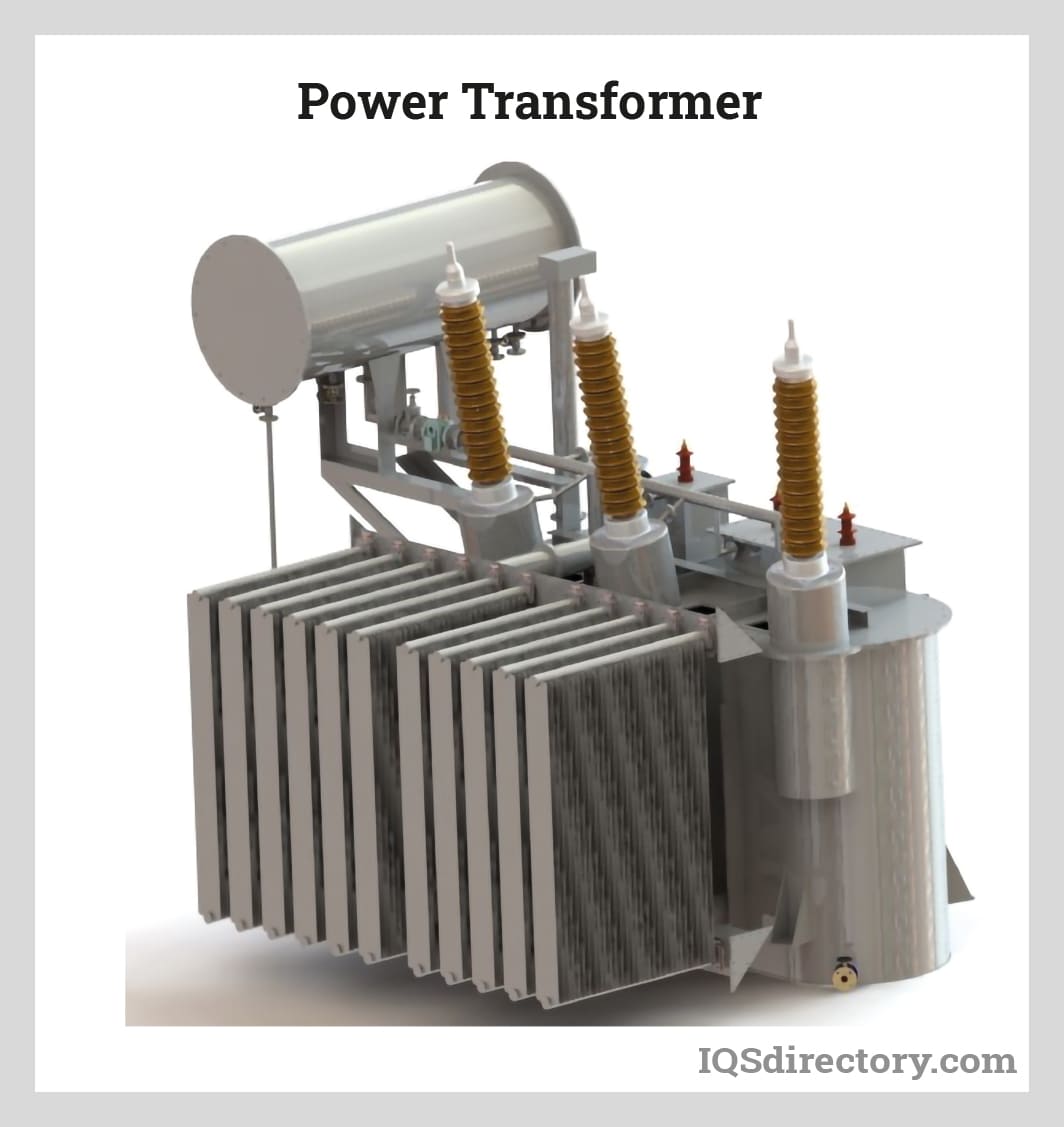

The functions of transformers are to step-up or step-down electrical current into voltages to match the requirements of electronics. Large transformers are a vital part of transporting electrical energy across long distances through power lines and grids. The use of transformers is an essential part of modern society. Read More…

With more than 500 current transformer manufacturers in the world, Triad Magnetics realizes you have a choice. Why choose Triad? Having served the needs of many industries for more than half a century, Triad believes its experience makes the difference. And if there is one point experience has taught it, it is that it must remain flexible and adaptable to the changing needs of the market.

At Acutran, we present ourselves as a dedicated manufacturer of electric transformers engineered to deliver dependable power conversion, long-term reliability, and consistent performance in demanding electrical applications. We design and build transformers that support efficient voltage regulation, electrical isolation, and system protection across industrial, commercial, and OEM environments.

At Prem Magnetics, Inc., we present ourselves as a dedicated manufacturer of electric transformers engineered to deliver reliable power conversion, electrical isolation, and consistent performance across demanding industrial and OEM applications. We focus on designing and producing transformers that support efficient energy transfer, stable voltage regulation, and long service life.

Established in 1973 manufacturing a wide variety of custom transformers and inductors. Transformer products range from small PC transformers to single-phase units with capacities between 10mW and 25KVA, as well as three-phase transformers from 7VA to 75KVA.

At Foster Transformer Company, we present ourselves as a dedicated manufacturer of electric transformers designed to deliver reliable power conversion, electrical isolation, and consistent performance across a wide range of industrial and OEM applications. We focus on building transformers that operate efficiently, manage heat effectively, and maintain stable electrical characteristics over long...

More Plug-In Transformer Manufacturers

While large transformers are part of large power grids, smaller transformers, of various sizes, are used for the safety and protection of electronics and different electrical devices. These compact transformers step-up or step-down the 120 volts that are commonly supplied to residences, stores, and office buildings to meet electrical requirements and provide a level of protection for smaller electronics.

A compact version of transformers is the plug-in transformer that is a convenient and small version of transformers that has found wide use as the number of electrical devices has rapidly grown in the 21st century. Plug-in transformers plug into electrical sockets and step-down voltage to match the needs of sensitive and intricate pieces of equipment. The use of plug-in transformers includes personal computers, computer systems, sound equipment, and production operations.

How Plug-In Transformers Change Power

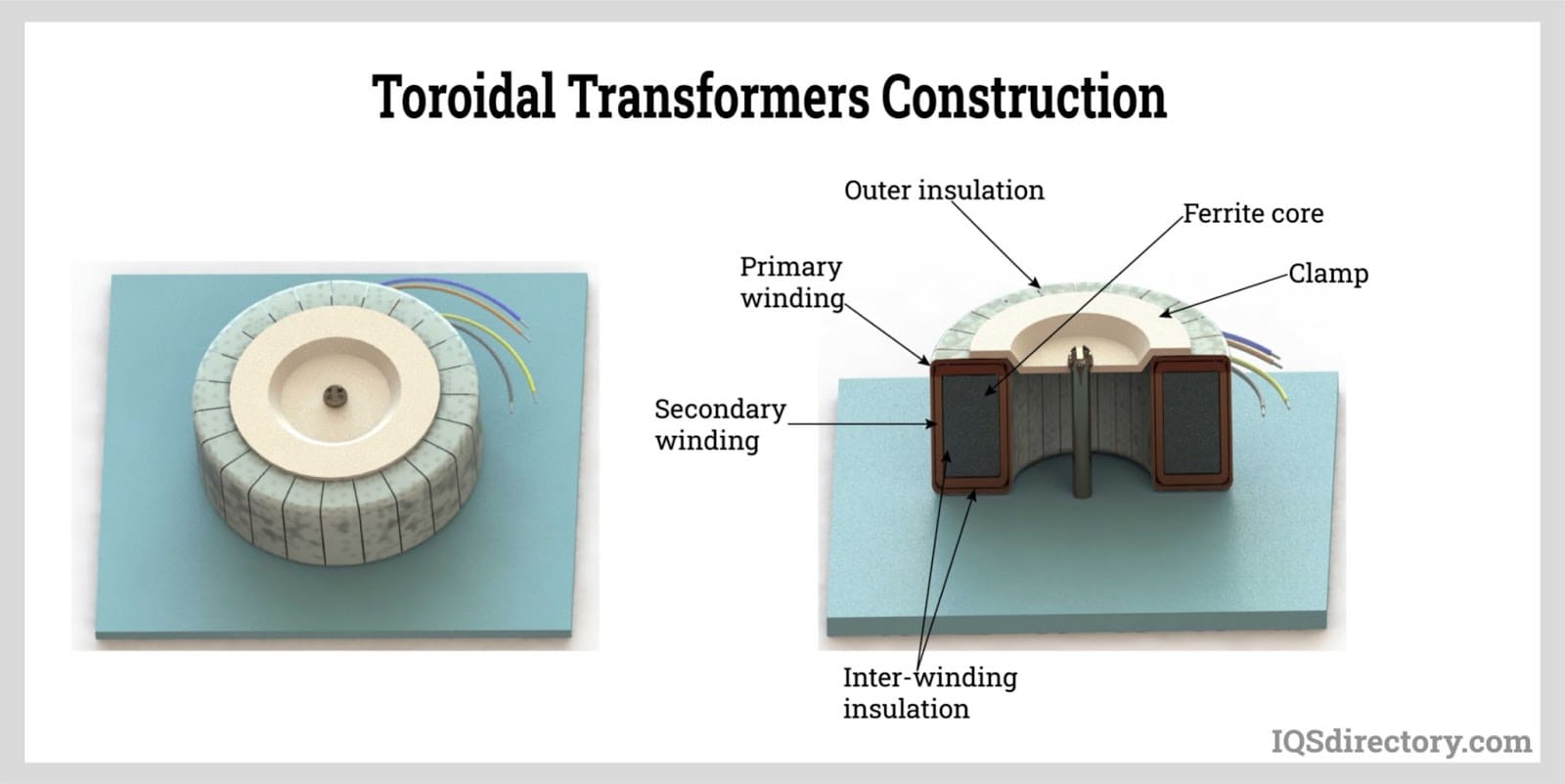

The structure of all transformers involves a core and windings. How each of these is oriented determines the types of transformers and have cores that can take different shapes including toroidal and cylindrical. Plug-in transformers can have varying shaped cores with most having simple cores due to their small size. In most cases, plug-in transformers consist of a core and two windings, designated as primary and secondary.

Primary Winding

The primary winding receives the energy from the alternating current (AC) source, which is normally a wall socket. Both windings of a plug-in transformer are made up of copper wire that has been wound around a magnetic core. As the power from the wall socket flows to the primary winding, it generates a magnetic field in the core. The number of windings, the core material, and the arrangement of the windings determine the efficiency of a plug-in transformer.

The designs of primary and secondary windings vary in accordance with their function. Plug-in transformers used in households and private homes do not require the same precision as plug-in transformers for sound studios and medical use. Regardless of the use of plug-in transformers, all versions have a primary winding that receives power from the energy source.

The primary winding is wrapped around the core and creates magnetic flux in the core, which stores the generated electrical energy. Homes and offices in the United States are provided with a current of 120 volts, which is received by the primary winding. The stored magnetic field in the core induces voltage and current in the secondary winding that will be transferred to the load.

Secondary Winding

The structure of the secondary winding is the same as that of the primary winding and includes copper wire that is wrapped around the core. While the cores of larger transformers can take different shapes, the cores for plug-in transformers are the same with variations in how the primary and secondary windings are wound.

Although the windings for the primary and secondary windings can be the same, in plug-in transformers, they have different ratios since the purpose of the transformer is to step-down the current for the load. The windings are the number of wires and their turns around the core. In most cases, for plug-in transformers, the windings of the secondary winding are a fraction of those for the primary winding in order to step-down the current.

The transfer of energy from the primary winding to the core to the secondary winding is through electromagnetic induction, which is the process of generating current in a conductor by changing it in a magnetic field. The stepped-down current is delivered from the secondary winding to the load.

Core

The core is the central part of any transformer as well as plug-in transformers. While the configurations of cores for transformers can take different forms, cores for all plug-in transformers are basically the same. The difference in plug-in transformer cores is in regard to how they are wound, which can vary from the primary and secondary wrapped around each other to being wound separately.

The common core of plug-in transformers is made of iron, steel or nickel. The quality of the core material determines the efficiency of a plug-in transformer and varies in accordance with how a plug-in transformer is used. The magnetic permeability and magnetic resistance of the core material determines the quality of a core, since the creation of a magnetic field to transfer current is essential to the performance of plug-in transformers. All aspects of plug-in transformers depend on the stability of the core, which provides structural support for the windings and a path for the magnetic flux. Current is received by the primary winding that creates magnetic flux that is stored by the core, from which the current moves on to the secondary winding and onto the load.

Plug-in transformer manufacturers work with their customers to select the right type of plug-in transformer for an application. Part of the selection process is advising customers as to the type of core. The cores of plug-in transformers for private use can fluctuate since the demands on a plug-in transformer are less critical. When a plug-in transformer is being chosen for more critical and professional use, the selection process involves careful consideration.

Windings

While the core is the central part of a plug-in transformer, the quality of the windings is another factor that determines its performance. The wires that are wound are made of aluminum or copper, with copper being the most common due to its high conductivity. Of the two materials, copper is heavier and bulkier but provides better performance while aluminum wire is lighter but not as conductive. Since aluminum is not as conductive as copper, more wire is required, which can increase the size of a plug-transformer.

The main function of plug-in transformers is to step-down the power input, which is received by the primary winding. The step-down process requires that the windings of the primary be greater than the windings of the secondary. The ratio between the two is always more than one with the primary being higher than the secondary and is written as numbers with a colon between them. For example, a ratio of 3:1 (3-to-1) indicates that the primary is receiving 3 volts while the secondary has 1 volt.

The step-down nature of the windings is necessary for the protection of the load and ensures that the load receives the proper voltage such that it won’t be damaged. Since the amount of electricity being transferred is so low, there is little danger of electronics overheating.

Resistance

Resistance is a term that is normally used when discussing the flow of electrical current. Wire resistance is an important factor in regard to the performance of plug-in transformers and is affected by the length of the wire, temperature, and thickness of the wire. Resistance opposes the flow of current and is the relationship between the applied voltage and current passing through. The calculation of wire resistance is determined by measuring the length of wire, its cross-sectional area, and the resistivity of the material from which the wire is made. While thicker wire has lower resistance, the use of thicker wire in the manufacture of plug-in transformers is difficult due to their smaller size.

Conclusion

The use of plug-in transformers is ever-expanding and necessitates an understanding of their use since they are a vital part of international travel and the protection of sensitive equipment. Regardless of the somewhat complex nature of their construction, plug-in transformers are easy to use but should be carefully matched with the device to which they are connected.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services