More Electric Transformer Manufacturers

As alternating current (AC) courses through the primary winding of a transformer, it generates a dynamic magnetic field around the transformer’s core. This ever-shifting electromagnetic field, in turn, induces a voltage across the secondary winding through the principle of electromagnetic induction. Depending on the transformer’s configuration—whether it’s a step-up or step-down transformer—this process can either elevate or reduce the power output, adapting voltage levels to meet specific electrical system requirements.

Components of Electric Transformers

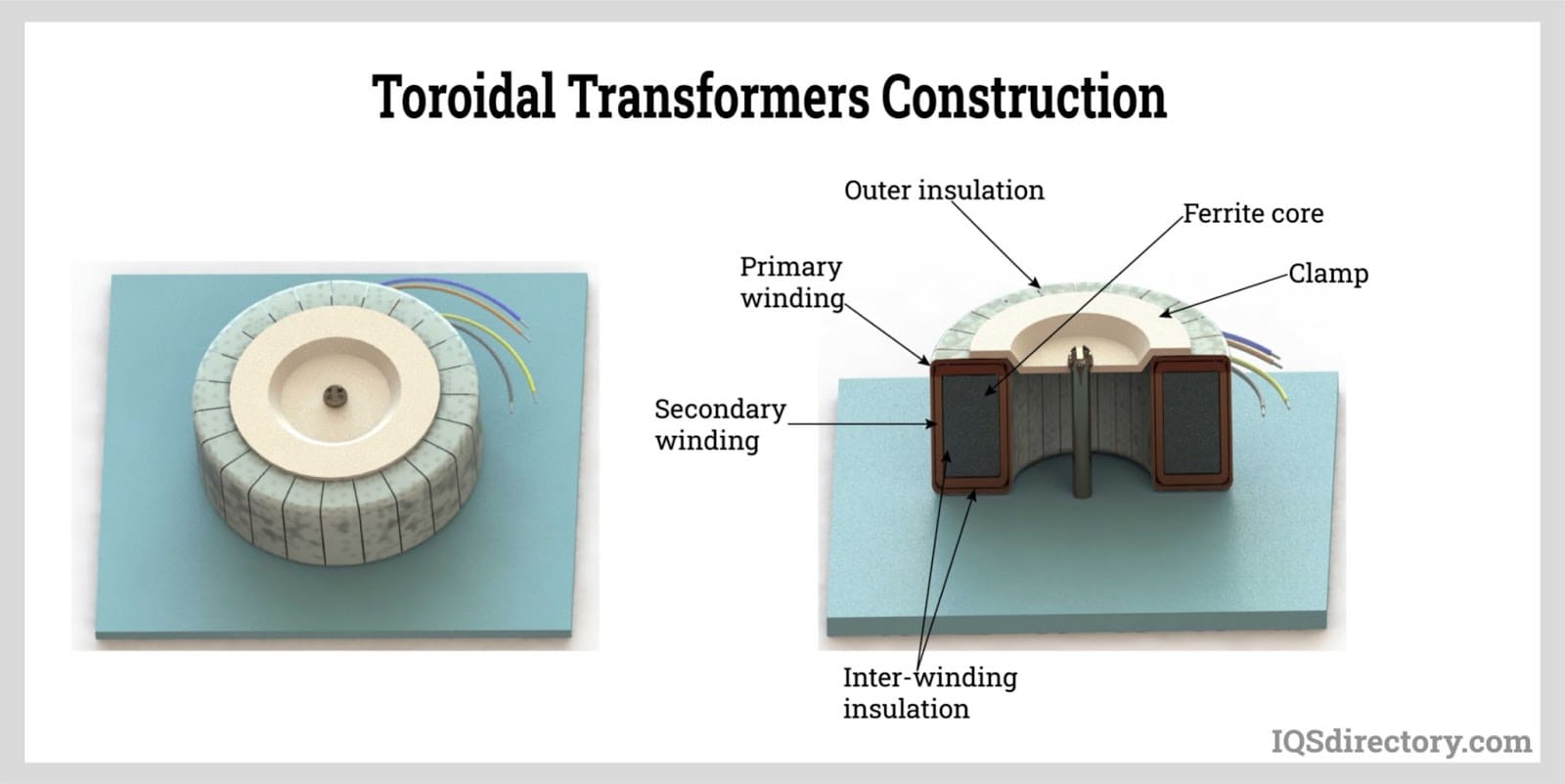

Electric transformers are intricate and highly engineered devices designed to reliably and efficiently transfer electrical energy from one voltage level to another. At their heart lies the transformer core, constructed from stacked laminated silicon steel sheets. This core acts as the essential conduit for magnetic flux, ensuring optimal magnetic coupling between the primary and secondary windings. The high permeability of the steel core minimizes eddy current and hysteresis losses, which is crucial for effective electromagnetic induction and for keeping energy losses at bay.

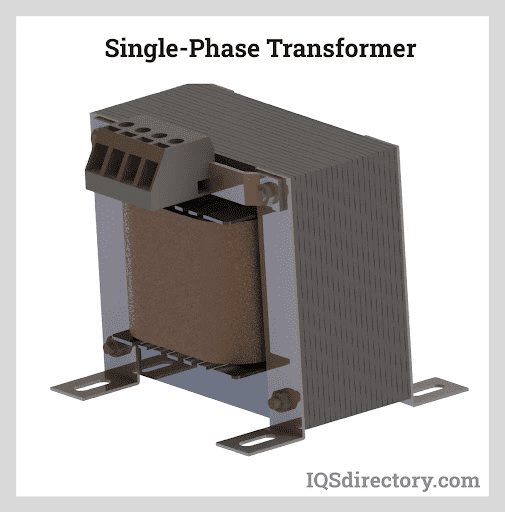

Encircling the core are the transformer windings, made from high-conductivity copper or, in some cases, aluminum. These windings are meticulously insulated to prevent short circuits and electrical faults. The primary winding receives AC voltage and current, initiating the magnetic field, while the secondary winding harvests this field to produce a transformed voltage—either higher or lower, depending on the application. The voltage transformation ratio is governed by the number of turns in the primary and secondary windings: more turns in the secondary winding yield a step-up transformer, while fewer turns result in a step-down transformer. This fundamental design enables transformers to adapt voltage for power transmission, distribution, and a wide array of industrial uses.

Insulation stands as the guardian of transformer design, essential for both safety and reliability. Employing advanced insulating materials such as varnishes, tapes, pressboard, and insulating papers, transformer insulation acts as a robust barrier against short circuits, dielectric breakdown, and damage under the intense pressures of high voltages. By braving electrical stresses and warding off environmental threats like temperature fluctuations, chemical exposure, dust, and moisture, proper insulation not only prolongs the operational life of a transformer but also ensures its safe and stable performance in demanding environments.

Some transformers incorporate a tap changer—a versatile component that allows for adjustment of the windings’ turn count. This tap-changing functionality is crucial for regulating output voltage in response to fluctuations in input voltage or changing load demands. By manipulating the tap changer, operators can fine-tune the transformer’s output to maintain consistent voltage levels, ensuring power quality and reliability for sensitive equipment or critical infrastructure.

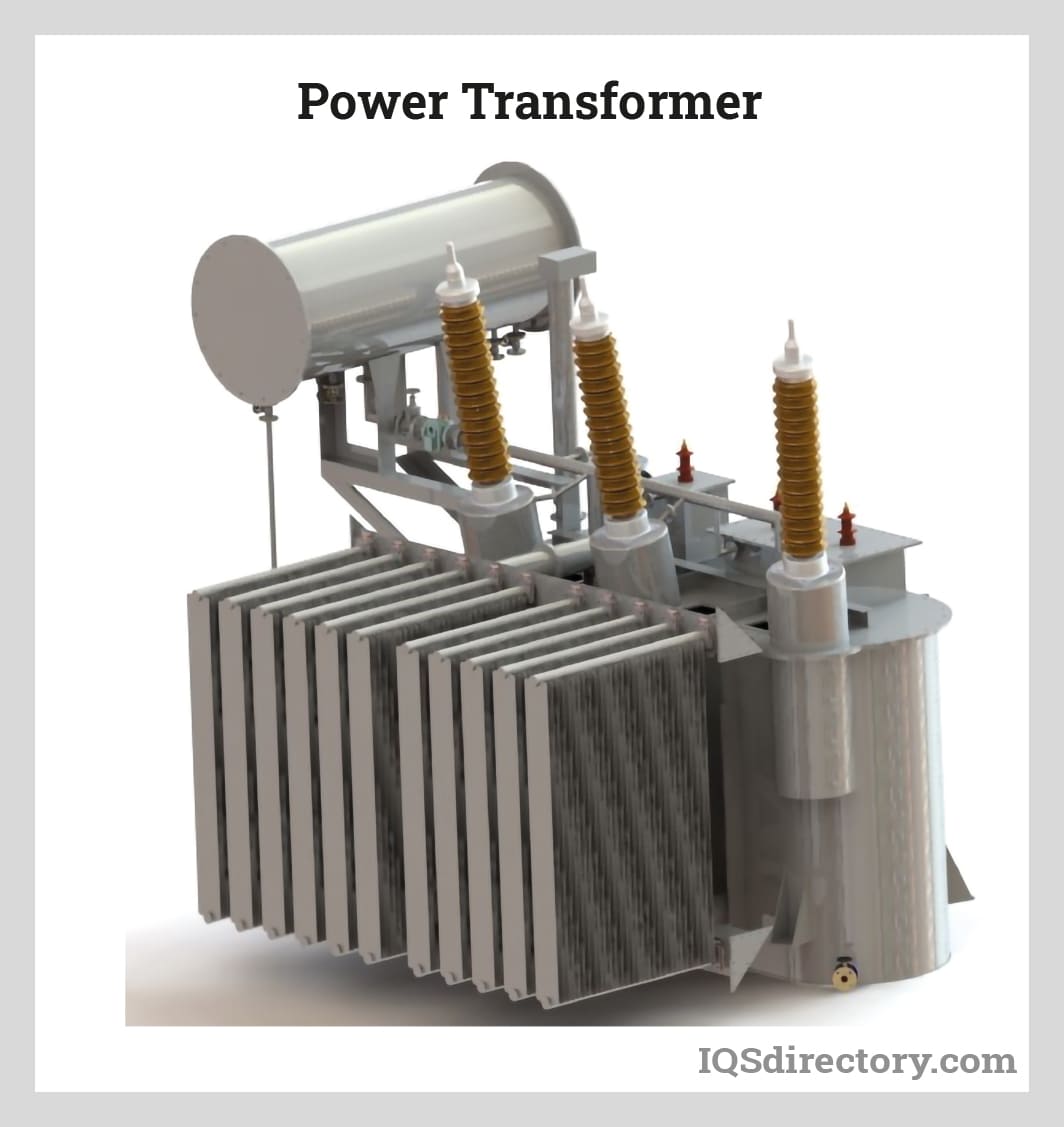

Transformers inherently generate heat as a byproduct of electrical resistance (I²R losses) and magnetic losses in their windings and core. To ensure safe operation and longevity, an efficient transformer cooling system is essential. The two primary cooling techniques are oil-immersed (liquid cooling) and dry-type (air cooling) systems. Liquid cooling—using mineral oil, synthetic esters, or biodegradable fluids—immerses the core and windings in a cooling medium, effectively dissipating heat via convection and conduction. Air-cooled transformers, meanwhile, rely on fins, radiators, or forced air circulation to transfer heat to the environment. Proper temperature management is vital for preventing insulation breakdown, preserving performance, and extending transformer lifespan.

The collective function of the core, windings, insulation, tap changer, and cooling system is to facilitate smooth, efficient, and safe power transfer. The core enhances magnetic coupling; windings enable mutual induction; insulation ensures safety and reliability; the tap changer allows voltage regulation; and the cooling system dissipates heat. Together, these components empower transformers to operate effectively across diverse electrical systems, from high-voltage transmission networks to industrial plants and residential power distribution.

Functioning of Electric Transformers

Transformers operate on fundamental principles of electromagnetic induction. When alternating current flows through the primary coil, it creates a time-varying magnetic field that passes through the transformer core. This changing magnetic flux induces an electromotive force (EMF), or voltage, in the secondary coil. The resulting voltage in the secondary winding is directly proportional to the ratio of turns between the secondary and primary windings—a characteristic known as the transformer turns ratio.

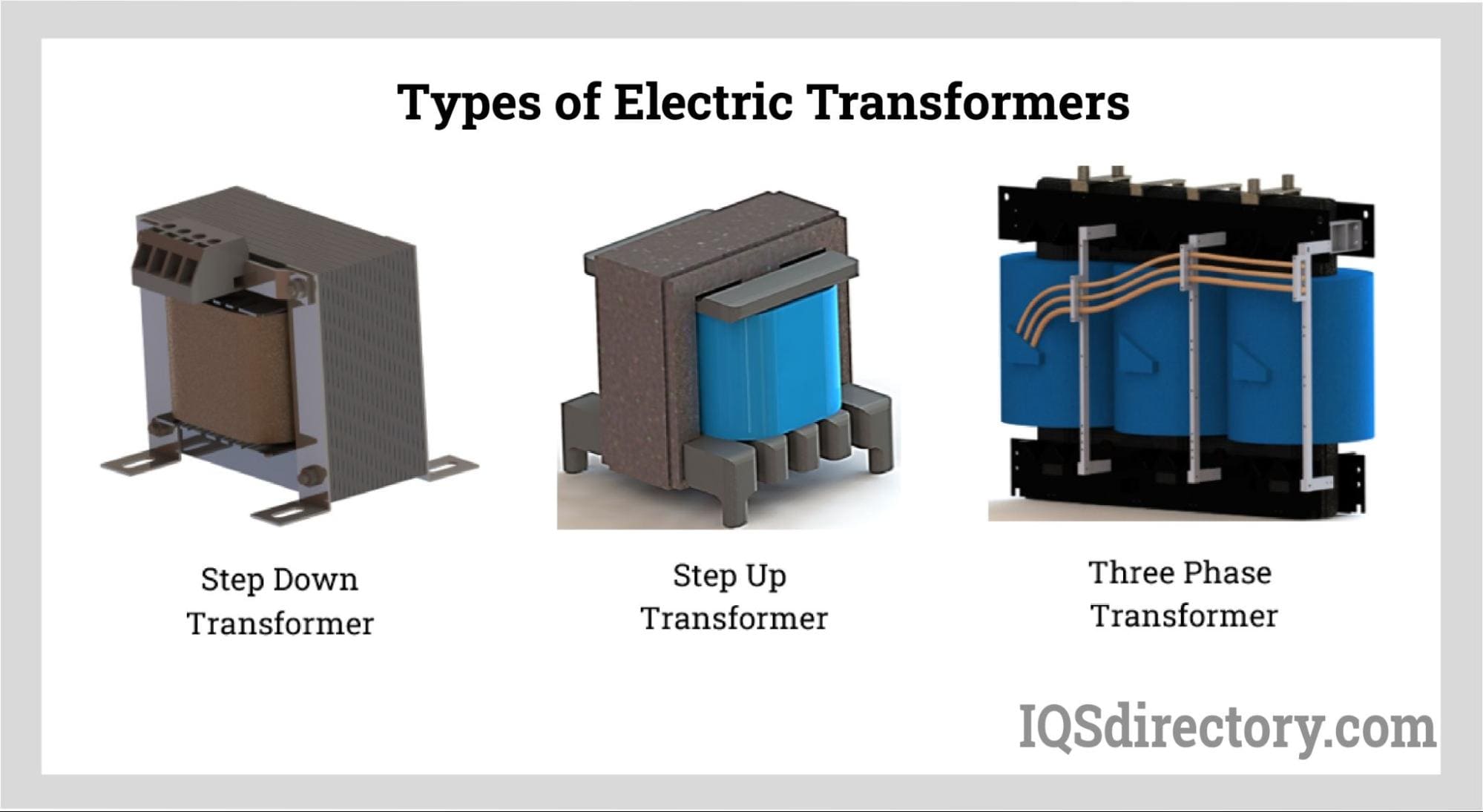

Transformers are categorized by the voltage levels they are designed to handle and their specific functions in the power system. Common types include:

- Step-up transformers: Increase voltage from primary to secondary to enable efficient long-distance power transmission.

- Step-down transformers: Decrease voltage for safe distribution and end-use in commercial, industrial, and residential applications.

- Distribution transformers: Manage voltage levels at the final stage of power delivery, ensuring safe and reliable electricity for homes and businesses.

- Isolation transformers: Electrically isolate circuits to prevent shocks and protect sensitive equipment.

- Instrument transformers: Measure voltage and current safely (potential transformers and current transformers).

Want to know more about how transformers work? What is the difference between a step-up and step-down transformer? How do you select the right transformer for your application? Explore our in-depth guides or connect with leading transformer manufacturers for tailored advice.

Variations of Electric Transformers

Electric transformers are engineered in a multitude of designs to suit specific roles within power transmission, power distribution, measurement, and specialized industry applications. Understanding these variations is crucial for selecting the right transformer for your project or facility.

Step-up transformers are typically found in power generation facilities. They elevate the voltage from the generator output to high levels suitable for efficient transmission over long distances via high-voltage transmission lines. This voltage increase reduces current, thereby minimizing transmission losses (I²R losses)—a key factor in the economic and practical delivery of electricity across regions and countries.

Step-down transformers perform the opposite function. Found in substations and local distribution networks, they reduce the high voltages used in transmission lines to safer, more manageable levels for downstream distribution to commercial buildings, factories, and residential neighborhoods. This voltage step-down process ensures that electrical power is both usable and safe for end-users.

Distribution transformers serve as the final voltage transformation step in the electric power distribution system. Typically pole-mounted or pad-mounted, these units provide the last voltage reduction, ensuring the electricity delivered to homes, retail stores, and small businesses is at the correct and safe voltage level.

Isolation transformers are designed to electrically separate the primary and secondary windings. This isolation protects people and sensitive devices from electric shocks, ground loops, and electromagnetic interference. You’ll find isolation transformers in medical devices, laboratory equipment, industrial control panels, audio-visual systems, and communication networks—anywhere safety and signal integrity are critical.

Instrument transformers are specialized devices that enable the safe measurement and monitoring of high-voltage systems. They include:

- Potential transformers (PTs)/Voltage transformers (VTs): Step down high voltages to standardized levels for instrumentation and relays.

- Current transformers (CTs): Reduce high currents to lower, measurable values for meters and protective relays.

Instrument transformers are essential for ensuring safety, accuracy, and reliability in power system measurement, protection, and automation.

Three-phase electric transformers are fundamental in industrial and commercial power distribution, supporting three-phase power systems that deliver greater power density and efficiency than single-phase systems. With three sets of windings, these transformers are used for heavy-duty machinery, large-scale HVAC systems, and continuous process industries that demand stable and balanced power supply.

Auto transformers are unique in that they use a single, continuous winding with taps to provide variable voltage outputs. These transformers are cost-effective and compact, making them ideal for voltage regulation, motor starting, and laboratory applications where only a small voltage adjustment is required. However, since auto transformers do not provide electrical isolation, they are not suitable for all safety-critical environments.

Current transformers—as a subset of instrument transformers—are indispensable for energy metering, monitoring, and circuit protection. They enable accurate current measurement in high-voltage systems, facilitating the safe and efficient operation of switchgear, protective relays, and remote monitoring systems.

From large-scale power generation to niche industrial processes, the diversity of electric transformer types ensures that every electrical demand—regardless of complexity or scale—can be met safely and efficiently. Looking for transformer solutions for specialized industries? Contact our experts or browse our manufacturer directory to find the right fit for your project.

Limitations and Overcoming Them

Despite their essential role in modern power systems, electric transformers face several inherent limitations and challenges. Understanding these is crucial for buyers, engineers, and facility managers evaluating transformer solutions:

- Energy losses: Transformers are not 100% efficient. Losses occur due to winding resistance (copper losses) and magnetic core losses (hysteresis and eddy currents), with energy dissipated as heat.

- Size and weight: High-capacity transformers, especially those for high-voltage transmission, can be large and heavy—posing challenges for transportation, installation, and space planning in urban or constrained environments.

- Reduced efficiency at light loads: Transformers are most efficient when operating close to their rated capacity. At low loads, fixed losses become proportionally significant, reducing overall efficiency.

- High-voltage challenges: Voltage surges, insulation failure, and corona discharge (especially at extra-high voltages) can lead to power losses, noise, ozone formation, and environmental concerns.

Transformer manufacturers are addressing these challenges through continuous innovation:

- Advanced materials: The adoption of amorphous steel and nano-crystalline alloys for transformer cores reduces core losses and improves efficiency.

- Smart transformer technologies: Integration of digital monitoring and control systems enables real-time performance tracking, predictive maintenance, and rapid fault detection—minimizing downtime and optimizing energy use.

- Superconducting transformers: Research into high-temperature superconductors aims to create transformers with negligible resistance, minimal losses, and significantly reduced size and weight.

- Eco-friendly cooling solutions: Use of biodegradable, fire-resistant natural ester fluids and advanced heat-exchange systems for better cooling and reduced environmental impact.

- Recycling and refurbishment: Programs to refurbish, upgrade, and recycle aging transformers help extend asset life and reduce waste, supporting circular economy initiatives in the power sector.

These advancements reflect the industry’s commitment to boosting transformer efficiency, reliability, and environmental sustainability. How do you assess transformer efficiency? What are the latest trends in eco-friendly transformer design? Explore our technical resources or consult with leading manufacturers for detailed information tailored to your application.

Agencies Overseeing Electric Transformers

In the United States, a network of regulatory and standards organizations governs the development, manufacturing, and deployment of electric transformers, ensuring safety, interoperability, and grid reliability. Key agencies and their roles include:

- National Fire Protection Association (NFPA): Publishes the National Electrical Code (NEC), which sets safety standards for transformer installation and operation.

- Federal Energy Regulatory Commission (FERC): Regulates interstate electricity transmission and market practices, focusing on transformer reliability and compliance.

- North American Electric Reliability Corporation (NERC): Enforces reliability standards for the bulk power system, including transformer operation, protection, and emergency preparedness.

- Institute of Electrical and Electronics Engineers (IEEE): Issues technical guidelines (such as IEEE C57 standards) for transformer design, testing, and performance.

- National Institute of Standards and Technology (NIST): Oversees accuracy in electrical measurements and metrology, supporting transformer calibration and certification.

- U.S. Department of Energy (DOE): Promotes research, development, and deployment of energy-efficient transformers, and establishes minimum efficiency standards.

These organizations collaborate to set benchmarks, drive innovation, and ensure that electric transformers meet safety, environmental, and technical requirements across the nation’s electrical grid. Curious about transformer certification? Looking for compliance guides or testing protocols? Visit our resources section for in-depth information or connect with accredited transformer suppliers for compliance support.

Applications of Electric Transformers

Electric transformers are foundational to modern infrastructure, powering an extensive array of industries and applications. Their versatility and reliability make them indispensable in:

- Power Generation: Transformers at generating stations step up voltage for efficient long-distance transmission, minimizing losses and enabling grid connectivity.

- Power Transmission: Substation and transmission transformers facilitate the movement of electricity across vast distances, interconnecting regional and national grids.

- Power Distribution: Distribution transformers step down voltage for safe delivery to homes, offices, shopping centers, and small businesses.

- Manufacturing: Industrial transformers supply tailored voltages to heavy machinery, robotics, conveyor systems, and automation equipment, supporting efficient production processes.

- Transportation: Traction transformers power electric trains, subways, and trams, ensuring smooth, efficient mass transit in urban and intercity networks.

- Telecommunications: Reliable transformers power data centers, base stations, and network infrastructure, safeguarding continuous communication and data flow.

- Mining: Rugged transformers deliver power to drills, hoists, pumps, and ventilation systems in remote and challenging conditions.

- Oil and Gas: Transformers support upstream, midstream, and downstream operations by powering pumps, compressors, refineries, and offshore platforms.

- Military and Defense: Military-grade transformers enable mission-critical radar, communications, and surveillance systems in the harshest environments.

- Medical Facilities: Isolation and precision transformers ensure stable, reliable power for imaging equipment (MRI, X-ray, CT scanners), life-support devices, and laboratory instruments.

- Renewable Energy: Transformers in solar, wind, and battery storage systems facilitate grid integration and efficient power management in decentralized energy networks.

Transformers are also pivotal in research laboratories, aerospace applications, event venues, and wherever reliable, noise-free, and precisely controlled electrical energy is required.

Not sure which transformer suits your business or project? Which transformer is best for industrial automation? How do you size a transformer for a renewable energy system? Use our expert guides or reach out to our network of manufacturers for tailored recommendations and custom solutions.

The Future of Electric Transformers

The landscape of electric transformer technology is rapidly evolving, driven by trends in smart grid integration, renewable energy, digitalization, and sustainability. Future transformers are expected to showcase:

- Smart and digital features: Integration of sensors, IoT connectivity, and advanced analytics for real-time monitoring, predictive maintenance, and automated control, fostering grid stability and operational efficiency.

- High-efficiency materials: Adoption of amorphous and nano-crystalline core materials, advanced insulation, and low-loss windings to further minimize energy losses and reduce operational costs.

- Superconducting transformers: Research into superconductors promises ultra-compact, lightweight transformers with negligible resistance and unprecedented efficiency—ideal for next-generation power systems.

- Bidirectional power flow: As distributed generation (solar, wind, batteries) and microgrids grow, transformers will increasingly support bidirectional energy flow, dynamic voltage regulation, and decentralized control.

- Eco-friendly design: Use of recyclable, biodegradable materials, and adoption of green manufacturing practices to lessen environmental impact and support sustainability goals.

Transformers will play a central role in supporting electric vehicle (EV) charging infrastructure, microgrids, energy storage integration, and the proliferation of decentralized renewable energy systems. As the energy sector embraces digital transformation and decarbonization, the next generation of transformers will deliver greater intelligence, flexibility, and resilience.

Stay up to date with the latest transformer technology trends! What are the benefits of digital transformers? How will smart grid technology impact transformer selection? Explore our blog or sign up for industry updates to stay informed.

Choosing the Right Electric Transformer Supplier

Achieving optimal performance, safety, and long-term value from your electric transformer investment starts with selecting the right supplier. Here’s how our comprehensive transformer manufacturer directory streamlines the evaluation and procurement process:

- Compare Multiple Suppliers: Access detailed business profiles highlighting each supplier’s expertise, industry focus, product range, certifications, and capabilities.

- Direct Inquiries and Quotes: Use the built-in contact forms to request information, technical specifications, or custom quotes directly from manufacturers and distributors.

- Website Previewer: Leverage our patented website previewer to quickly assess each company’s specialties, product lines, and industry experience—saving you valuable research time.

- Streamlined RFQ Process: Submit a single, easy-to-use Request for Quote (RFQ) form to reach out to multiple suppliers at once, accelerating your sourcing and procurement decisions.

- Expert Guidance: Access technical resources, application case studies, and buying guides to inform your decision-making process and ensure you choose the most suitable transformer for your needs.

When evaluating electric transformer suppliers, consider key decision factors such as:

- Product quality and compliance with industry standards (IEEE, IEC, UL, CSA, etc.)

- Customization capabilities for unique voltage, current, or environmental requirements

- After-sales support, maintenance services, and warranty programs

- Energy efficiency ratings and life cycle cost analysis

- Lead times, logistics, and availability of technical documentation

Ready to take the next step? Which supplier offers the transformer features your project demands? How do you compare transformer quotes and specifications? Start your search in our manufacturer directory, or contact us for personalized assistance with your transformer sourcing strategy.

For more information on electric transformers, industry standards, or to request a quote from leading manufacturers, explore our comprehensive listings and technical resources. Empower your business with the right transformer solution—engineered for efficiency, safety, and long-term reliability.

How does an electric transformer work?

An electric transformer operates on the principle of electromagnetic induction. Alternating current (AC) passing through the primary winding generates a changing magnetic field in the core, which induces a voltage in the secondary winding. The resulting voltage depends on the ratio of turns between the primary and secondary coils, allowing the transformer to either increase (step-up) or decrease (step-down) voltage as needed.

What are the main components of an electric transformer?

The main components of an electric transformer include the core (usually made from laminated silicon steel to direct magnetic flux), primary and secondary windings (typically copper or aluminum cables), insulation (to prevent electrical faults), tap changer (for voltage regulation), and a cooling system (which may be oil-immersed or air-cooled) to dissipate heat generated during operation.

What is the difference between a step-up and a step-down transformer?

A step-up transformer increases the output voltage compared to the input by having more turns in the secondary winding, making it ideal for transmitting electricity over long distances. A step-down transformer decreases the voltage by having fewer turns in the secondary, making the power suitable and safe for end-use in homes and businesses.

Why is insulation important in electric transformers?

Insulation is crucial for electric transformers because it prevents short circuits and protects against dielectric breakdown at high voltages. Insulation materials such as varnishes, tapes, and insulating papers help transformers withstand electrical and environmental stress, ensuring operational safety and extending the unit’s lifespan.

What are the most common types of electric transformers and their uses?

Common types of electric transformers include step-up transformers for increasing voltage in power transmission, step-down transformers for lowering voltage for distribution, distribution transformers for end-user delivery, isolation transformers for circuit separation and safety, and instrument transformers (potential and current transformers) for measuring voltage and current safely in high-voltage systems.

What are the main limitations of electric transformers and how are they being addressed?

Electric transformers face limitations such as energy losses (from winding resistance and core losses), large size and weight, reduced efficiency at light loads, and insulation challenges at high voltages. Manufacturers are addressing these with advanced core materials (e.g., amorphous steel), smart monitoring technologies, eco-friendly cooling solutions, and research into superconducting transformers to minimize losses and environmental impact.

Which agencies oversee electric transformer standards and compliance in the United States?

Agencies regulating electric transformers in the U.S. include the National Fire Protection Association (NFPA), Federal Energy Regulatory Commission (FERC), North American Electric Reliability Corporation (NERC), Institute of Electrical and Electronics Engineers (IEEE), National Institute of Standards and Technology (NIST), and the U.S. Department of Energy (DOE). These organizations set safety, performance, and efficiency standards for transformer manufacturing and operation.

How do you choose the right electric transformer supplier?

To choose the right electric transformer supplier, compare multiple manufacturers based on their product quality, certifications, customization capabilities, after-sales support, energy efficiency ratings, and compliance with industry standards. Using a comprehensive supplier directory can streamline evaluation and procurement, while technical resources and expert guidance ensure you find the best transformer for your specific needs.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services