Step up transformers are a very common tool used in power transforming and modification applications; they are typically the first major transformer in a power transmission system and are often used in multiple locations throughout the system. An example of this would be in power plants. Read More…

With more than 500 current transformer manufacturers in the world, Triad Magnetics realizes you have a choice. Why choose Triad? Having served the needs of many industries for more than half a century, Triad believes its experience makes the difference. And if there is one point experience has taught it, it is that it must remain flexible and adaptable to the changing needs of the market.

At CES Transformers, we dedicate ourselves to designing and manufacturing high-quality electric transformers that power industrial, commercial, and utility applications across the nation. We take pride in combining advanced engineering with decades of hands-on expertise to deliver reliable performance and lasting value. Every transformer we build reflects our commitment to precision, safety, and...

At Spang Engineered Solutions, we specialize in designing and manufacturing high-performance electric transformers that meet the demands of today’s advanced power and control systems. We take pride in engineering solutions that go beyond standard components, combining innovation and precision to deliver superior magnetic and electronic performance.

Established in 1973 manufacturing a wide variety of custom transformers and inductors. Transformer products range from small PC transformers to single-phase units with capacities between 10mW and 25KVA, as well as three-phase transformers from 7VA to 75KVA.

At Olsun Electrics Corporation, we specialize in crafting high-quality electric transformers designed to meet the diverse needs of our customers. Our expertise extends to providing comprehensive solutions that encompass design, manufacturing, and testing, ensuring that every transformer we produce delivers exceptional performance and reliability.

More Step Up Transformer Manufacturers

Step Up Transformers: How They Work, Key Benefits, and Industry Applications

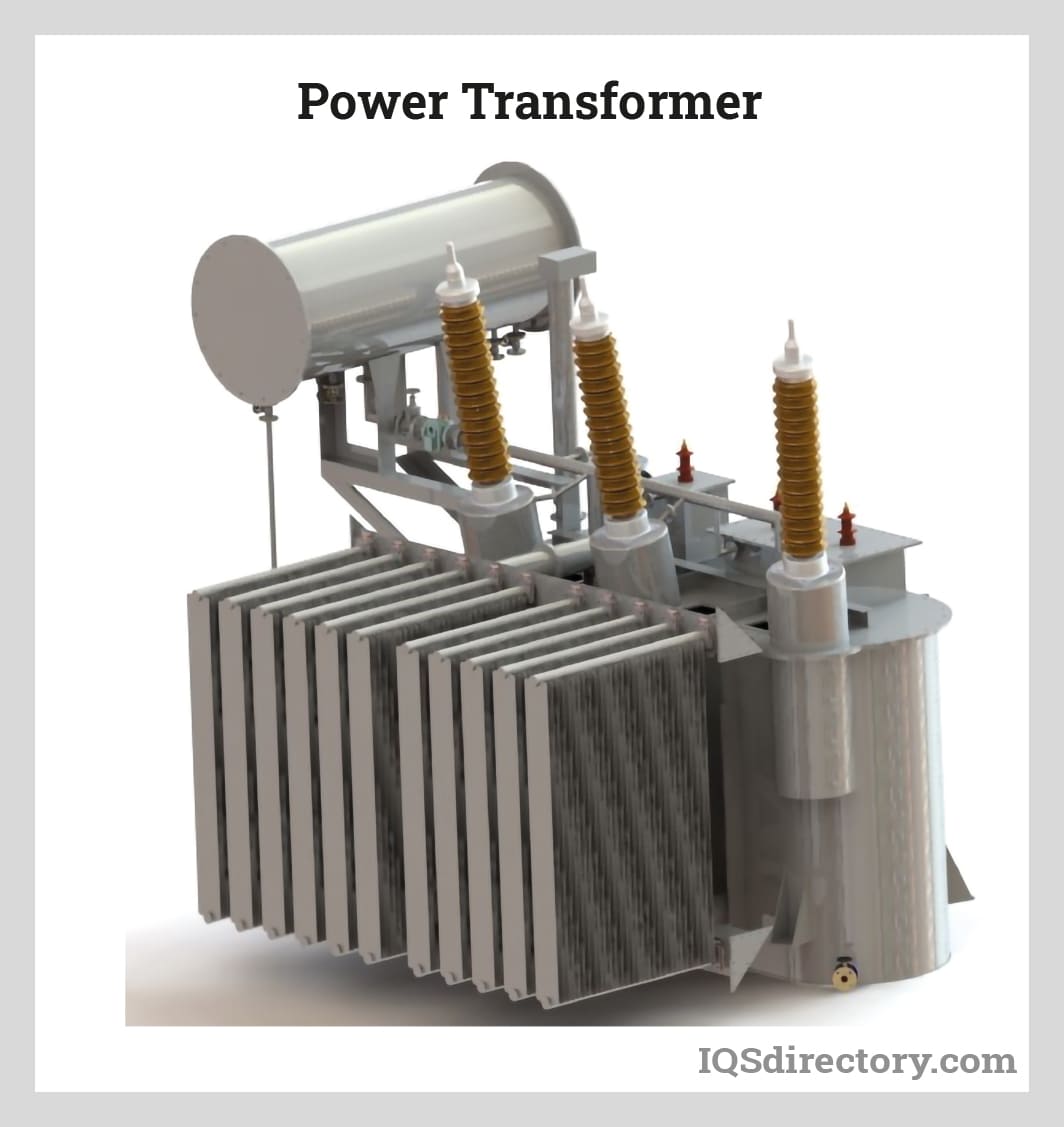

Electricity transmission over long distances presents significant challenges, chief among them being energy loss due to resistance in power lines. High voltage transmission dramatically reduces these losses, making the distribution of electricity more efficient and cost-effective for utility providers and end users alike. This is where step up transformers play a crucial role in the modern power grid and industrial operations. By elevating the voltage of electricity before it leaves power plants, step up transformers ensure that energy can travel vast distances with minimal loss, supporting the reliable delivery of electrical power to homes, businesses, and critical infrastructure worldwide.

What Is a Step Up Transformer?

A step up transformer is an electrical device designed to increase (or "step up") the voltage from a lower value on the primary side to a higher value on the secondary side. This process enables the efficient transmission of electricity across long distances and is foundational to the global electrical distribution system. Step up voltage transformers are essential in utility-scale power generation, industrial automation, renewable energy systems, and various specialized applications where voltage conversion is required for optimal performance.

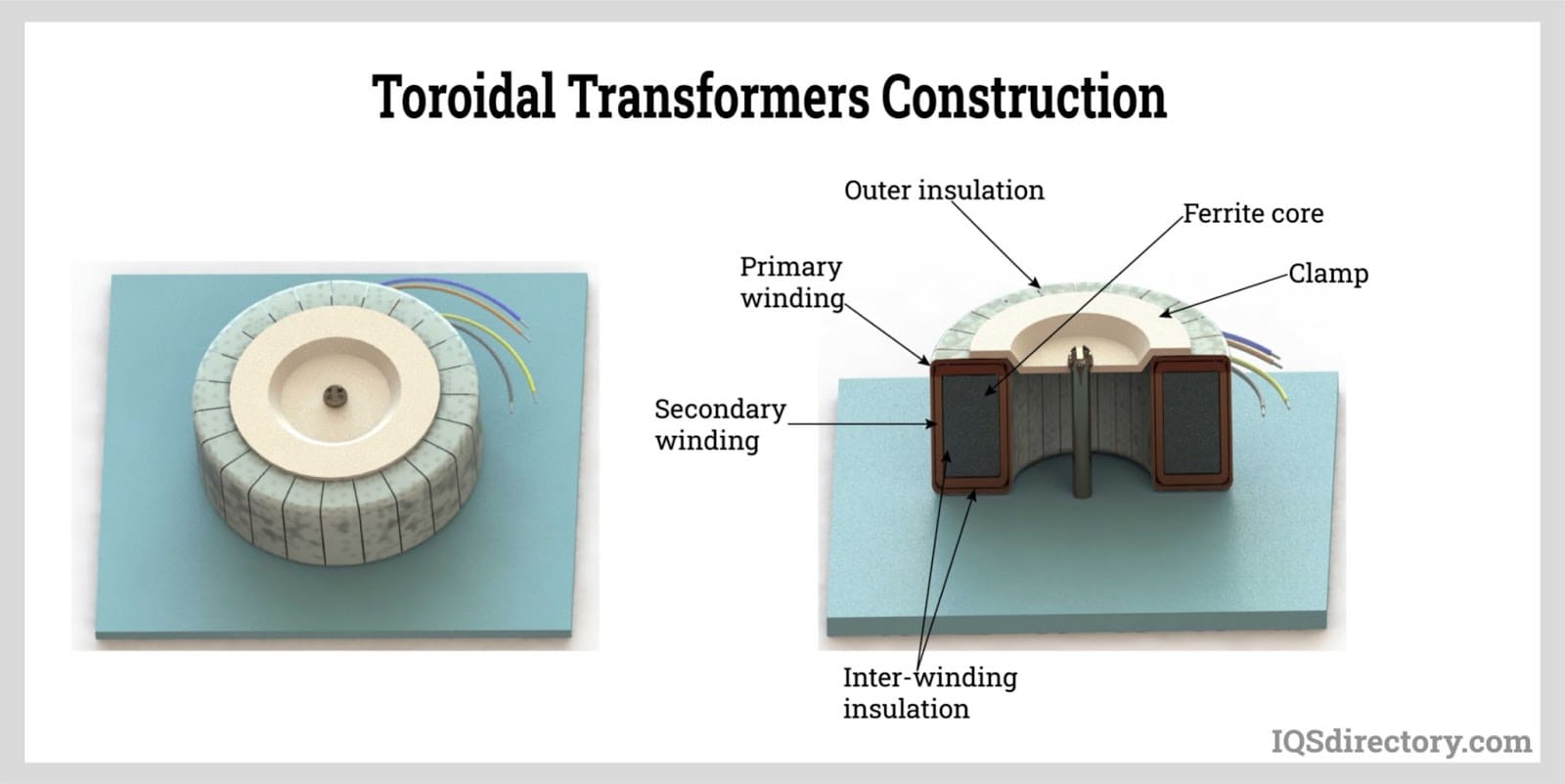

At its core, a step up transformer consists of two sets of coils—known as primary and secondary windings—which are linked by a magnetic field generated within the transformer’s core. The core itself may be constructed from high-permeability materials such as ferrite compounds or laminated steel, further enhancing the efficiency and performance of the transformer. The windings are typically made from copper, though other conductive materials like aluminum, nickel, and special steel alloys are also employed in certain designs to balance cost, efficiency, and durability.

How Does a Step Up Transformer Work?

The operation of a step up transformer is based on fundamental principles of electromagnetic induction. When alternating current (AC) flows through the primary coil, it creates a varying magnetic field that penetrates the transformer core. This changing magnetic field induces a voltage in the secondary coil, which, in a step up transformer, has more turns (windings) than the primary coil. The result: the voltage output on the secondary side is higher than the input voltage on the primary side.

The efficiency of this voltage transformation is governed by the transformer’s turns ratio—the ratio between the number of windings in the primary and secondary coils. For step up transformers, the secondary coil has significantly more turns than the primary, allowing for a substantial increase in voltage. Despite this increase in voltage, the overall power remains nearly constant (minus minor losses due to resistance and magnetic flux leakage), while the current decreases proportionally to conserve energy per the law of conservation of energy.

- Primary coil: Receives incoming low-voltage, high-current AC power from the source (such as a generator or power plant).

- Magnetic core: Provides a path for the magnetic field, linking the two coils and facilitating electromagnetic induction.

- Secondary coil: Outputs high-voltage, low-current AC electricity for transmission or use in downstream systems.

Wondering how step up transformers compare to step down transformers? The main difference lies in the direction of voltage transformation. Step up transformers increase voltage, while step down transformers (used for local distribution and device-level conversion) decrease voltage for safe use in residential, commercial, and industrial environments.

Step Up Transformer Construction and Materials

The performance and reliability of a step up transformer are heavily influenced by its construction and the quality of materials used. Copper windings are the industry standard for high-efficiency designs, as copper’s low electrical resistance minimizes energy loss during transmission. Some transformer manufacturers employ aluminum windings as a cost-effective alternative, though these are generally less efficient and may require larger conductors to handle the same current.

The transformer core is another critical component. It is typically made of laminated silicon steel or ferrite materials, which reduce eddy current losses and improve overall magnetic coupling between the windings. Advanced designs may incorporate specialized alloys—such as chromium or nickel steel—for enhanced heat resistance, mechanical strength, or performance in demanding environments.

Key construction considerations include:

- Core design: Laminated or toroidal cores are often selected for their ability to minimize energy losses due to eddy currents and hysteresis.

- Insulation: High-quality insulation ensures electrical isolation between windings and prevents short circuits or breakdowns under high-voltage stress.

- Cooling systems: Larger industrial transformers may utilize oil or air cooling systems to dissipate heat generated during operation, extending service life and maintaining efficiency.

- Protective enclosures: Weatherproof housings protect outdoor units from environmental hazards, while sealed designs are used in harsh or hazardous locations.

Curious about which type of transformer is best for your application? Contact leading transformer manufacturers to discuss custom solutions and recommendations for your specific voltage conversion needs.

Step Up Transformer Applications: Where Are They Used?

Step up transformers are integral to a wide range of industries and use cases, making them a cornerstone of modern electrical infrastructure. Some of the most common applications include:

- Power Generation and Transmission: Utility-scale power plants use step up transformers to convert generated electricity to extremely high voltages—often in the hundreds of kilovolts—prior to long-distance transmission. This minimizes energy loss and reduces the cost of delivering electricity to distant regions.

- Renewable Energy Systems: Solar farms and wind turbines output electricity at relatively low voltages. Step up transformers are used to match the output to grid-level voltages for integration into the larger power network.

- Industrial Automation and Manufacturing: Factories and processing facilities employ step up transformers to supply specialized equipment with the correct voltage, improving efficiency and safeguarding sensitive machinery.

- Medical and Scientific Equipment: Laboratories and hospitals often require high-voltage power supplies for diagnostic imaging, laser systems, and research instruments. Step up transformers provide precise, reliable voltage conversion for these critical applications.

- Telecommunications and Data Centers: High-voltage transformers are used to power transmission equipment, maintain signal integrity, and ensure the reliability of communications infrastructure.

- Consumer Electronics and International Travel: Travelers and business professionals use portable step up transformers to safely operate devices and appliances built for different voltage standards in foreign countries.

- Audio and Broadcasting: Step up transformers are found in audio amplifiers, radio transmitters, and studio equipment, where they are used to match impedance and optimize signal clarity.

Looking for a step up transformer for a specific project? Request a quote or technical consultation from experienced transformer suppliers to ensure you select the right product for your operational requirements.

Benefits of Step Up Transformers in Power Systems

The widespread adoption of step up transformers has transformed the way electricity is generated, transmitted, and distributed worldwide. Key advantages include:

- Reduced Transmission Losses: By increasing voltage and decreasing current, step up transformers minimize resistive losses in power lines. This allows utility companies to deliver electricity more efficiently and cost-effectively over vast distances.

- Improved System Reliability: High-voltage transmission enabled by step up transformers reduces the risk of brownouts and power interruptions, ensuring a stable supply of electricity for critical infrastructure.

- Scalability and Flexibility: Step up transformers can be designed for a wide range of voltage ratings and power capacities, supporting everything from small-scale industrial processes to massive grid interconnections.

- Cost Savings: Lower transmission losses translate into lower operational costs for utilities, which can result in more affordable energy prices for consumers and businesses.

- Environmental Benefits: Efficient power transmission reduces the need for additional generation capacity, lowering greenhouse gas emissions and supporting sustainability goals.

- Safety: By isolating the primary and secondary circuits, step up transformers help protect downstream equipment and personnel from electrical faults and surges.

How to Choose the Right Step Up Transformer: Buying Guide and Decision Factors

When selecting a step up transformer for your business, facility, or project, it’s essential to consider several technical and operational factors to ensure optimal performance and safety. Here are some critical questions to ask:

- What is the required input and output voltage? Determine the voltage levels you need to convert between (e.g., 120V to 480V, 220V to 11kV, etc.).

- What is the maximum load or power capacity? Assess the total wattage or VA (volt-ampere) rating required by your application.

- What is the frequency of operation? Most transformers are designed for standard power frequencies (50Hz or 60Hz), but specialized applications may require custom designs.

- What are the environmental conditions? Consider operating temperature, humidity, altitude, and exposure to dust, chemicals, or moisture.

- What safety standards and certifications are required? Check for compliance with UL, CSA, IEC, or other relevant regulatory standards.

- What are the installation requirements? Decide between portable, wall-mounted, or floor-standing units based on your available space and mobility needs.

Need help with transformer sizing or specification? Connect with a certified transformer manufacturer for expert guidance and custom engineering support tailored to your unique power conversion needs.

Step Up vs. Step Down Transformers: What’s the Difference?

Step up and step down transformers serve complementary roles in electrical distribution systems. While step up transformers increase voltage for efficient long-distance transmission, step down transformers reduce voltage at the point of use—making electricity safe for home appliances, office equipment, and industrial machinery. Both types rely on electromagnetic induction and similar construction principles, but their applications and voltage conversion directions differ.

For travelers and international businesses, step down transformers are especially important for converting higher local voltages to North American standards (such as 120V), allowing safe operation of sensitive electronics like laptops, fax machines, cellular phones, and answering machines. Without proper voltage conversion, there’s a risk of short-circuiting devices, damaging equipment, or even causing electrical fires.

Frequently Asked Questions (FAQs) About Step Up Transformers

What industries benefit most from step up transformers?

Step up transformers are indispensable in the utility, renewable energy, industrial automation, manufacturing, medical, broadcasting, and telecommunications sectors. They support reliable, efficient power delivery wherever high-voltage transmission or specialized equipment operation is needed.

How do I know if I need a step up transformer?

If your application involves increasing voltage for transmission, supporting high-voltage industrial equipment, or converting local supply to a higher voltage for specialized processes, a step up transformer is likely required. Consult with a transformer expert to review your system specifications and determine the best solution.

Can step up transformers be customized?

Yes. Many manufacturers offer custom step up transformer designs tailored to specific voltage ratings, environmental conditions, mounting options, and safety requirements. Custom solutions can improve efficiency, safety, and operational flexibility in demanding applications.

What maintenance do step up transformers require?

Routine inspections, cleaning, thermal imaging, and oil analysis (for oil-cooled units) help maintain transformer performance. Preventive maintenance reduces the risk of failure, extends service life, and ensures ongoing compliance with safety standards.

Are there portable step up transformers for travelers?

Absolutely. Portable step up transformers are widely available for international business travelers and expatriates, enabling safe use of electronics and appliances in countries with differing voltage standards.

Conclusion: Harnessing the Power of Step Up Transformers

Step up transformers are the backbone of global power transmission, enabling efficient, reliable, and scalable delivery of electricity across continents and industries. Whether you are designing a new renewable energy installation, upgrading industrial automation systems, or supporting global operations, selecting the right transformer is essential for safety, performance, and long-term value.

Ready to source a high-quality step up transformer for your project or facility? Contact premier transformer manufacturers today for expert advice, custom product options, and competitive pricing.

Explore related topics:

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services